When you pop off the faceplate the filament, idler and spring all come along too, as one neat assembly.

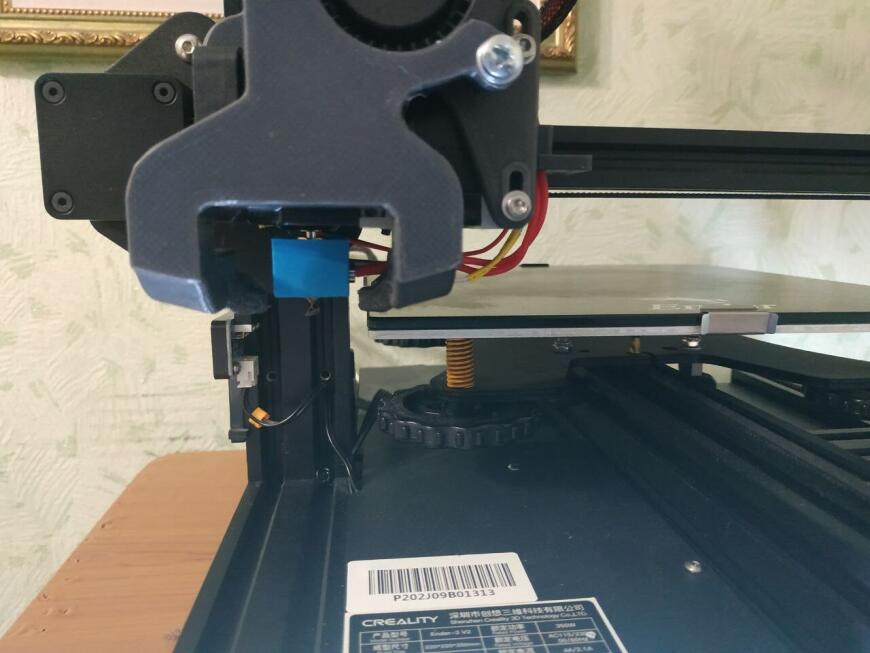

ENDER 3 V2 HEMERA FULL

Full access is available to clean and replace parts even while filament is loaded. Should you need to disassemble Hemera for maintenance, the internal mechanisms are easily accessible by removing the fan, and undoing the two faceplate screws. Filament tension is increased by rotating clockwise and decreased by rotating counterclockwise. To set filament tension the user simply twists a thumbscrew and a cam slider mechanism with a captive nut compresses a spring and loads the idler. User-centered DesignĪll interaction with Hemera is from the top. Hemera’ heatsink design ensures airflow is diverted up and away from both the HotEnd and the heated bed, reducing the risk of warping and uneven stresses forming in the printed part.

ENDER 3 V2 HEMERA PLUS

Hemera features convenient T-Slots for easy mounting to your printer, plus space for other accessories, part cooling fans and bed levelling probes to name a couple. This exceptional filament constraint also has a significant impact on printing rigid, and semi-rigid materials such as PLA or Nylon. You won’t experience the full extent of its unrivalled filament constraint until you print ultra-flexible materials. Hemera constrains filament like no other extrusion system, fact. It has a custom motor which is based on a NEMA17, along with our own faceplate designs which has allowed us to add our own features for user convenience, such as mounting slots as well as produce a very compact system.

Hemera is a system of components designed to work seamlessly together as a single compact product. The secondary gear shaft is on a moveable, sprung idler which allows the user to adjust filament tension. The E3D Hemera offers extraordinary filament control and allows the 3D printer user to take flexible printing to the next level, thanks to its super constrained filament path.įor E3D Hemera, we opted for a hardened stainless steel dual-drive arrangement which provides a huge boost in grip over single drive systems, in fact, we’re able to push filament with up to 10kg of force. Created by E3D to ensure high-quality components and durability. Simply add a Bowden adapter (sold separately) and your Hemera becomes a powerful Bowden filament drive.The E3D Hemera is a dual-drive extrusion system complete with a fully hardened stainless steel drive train and optimized heatsink design. Hemera works with both Bowden and Direct Drive setups. It is precisely lubricated by robots during assembly and has been thoroughly analyzed with an accelerated wear test to ensure that your Hemera will perform for many years. This creates high quality, consistent extrusion from the first to the last layer.Įvery Hemera contains shielded bearings and high-quality igus® bushings for optimal wear resistance. Sharp, individually machined hobb teeth provide excellent filament grip, and rounded surfaces help reduce filament buildup. Hemera's 3.32: 1 dual-drive gears generate up to 120N of thrust on either side of the filament for accurate, controlled extrusion without loss of torque. Air circulates up through the ribs and away from the 3D print, preventing inadvertent warping of the printed part. Hemera has a uniquely designed, lightweight aluminium heat sink to ensure highly effective cooling.

Hemera's stainless steel hobb teeth are wear-resistant, so with the right combination of components, your Hemera can effortlessly print advanced composite materials like carbon fibre-filled filaments. Even the softest flexible filaments are not a problem.

A narrow filament path provides excellent performance on difficult-to-print plastics such as flexible materials. Hemera is a combination of extruder and hotend, so it has fewer transitions than most of the extrusion systems available. He goes on to print an intricately designed castle in.

ENDER 3 V2 HEMERA UPGRADE

Thanks to the positive temperature coefficient (PTC), the Revo HeaterCore works more safely than comparable solutions on the market. Another great upgrade video from 3DMN for the Ender 3 shows the outstanding performance of the Hemera. Revo nozzles form a closed system of nozzle and heat break, which prevents undesired material leakage. Change the nozzles quickly and easily with your fingers.

0 kommentar(er)

0 kommentar(er)